Air Quality

Sunrise Site

Emissions

Husky is working to reduce its emissions, including capturing carbon dioxide, reducing energy consumption, minimizing fugitive emissions and mitigating flaring and venting.

The Company's air quality and climate change strategies include measuring and reporting greenhouse gas (GHG) emissions and criteria air contaminants, such as sulphur dioxide (SO2) emissions. This provides an opportunity to evaluate reported emissions and forecast at the corporate and individual facility level.

Husky meets emissions regulatory compliance in all jurisdictions, including third-party verification where required.

The Company's air emissions strategy is supported by its Environmental Performance Reporting System (EPRS), allowing for reports that are consistent, and that can be reproduced and audited.

Data is based on gross operations, as at Dec. 31, 2013. Drilling and completions emissions are estimated and reported as required by jurisdictions.

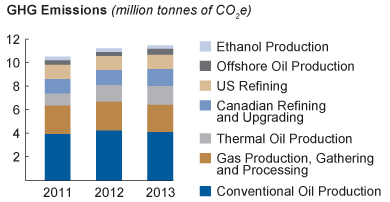

The 2.2 percent increase in GHG emissions over 2012 can be attributed to increased thermal production, a temporary change in process conditions at the Lloydminster Upgrader and increased production in the Atlantic Region due to an offstation the year before. This was offset by a slight decrease in Western Canada production.

In 2013 Husky adopted new global warming potentials used for calculating carbon dioxide equivalency for corporate emissions and emissions for past years have been recalculated on that basis.

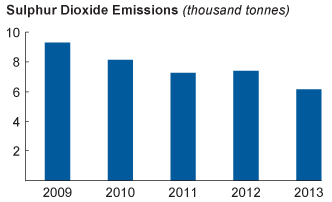

Decrease in 2013 emissions is attributed to a reduction in inlet volumes and an increase in sulphur processing efficiency at the Ram River Gas Plant.

Gas Conservation

As part of reducing its emissions, Husky conserves gas from operations where it is practical and economic. The focus is on complying with regulatory requirements and using technology to improve operational emissions performance.

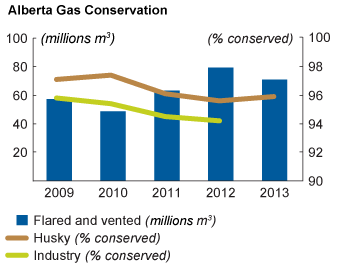

The Company estimates overall solution gas conservation at its Alberta operations in 2013 was 95.9 percent, an increase from 95.6 percent in 2012. Data from the annual Alberta Energy Regulator's Upstream Petroleum Industry Flaring and Venting Report shows Husky's gas conservation in the province between 2009 and 2012 was above the industry average.

Last year, the Company’s upstream flaring and venting volumes in Alberta decreased 10.5 percent from the year before.

Source: 2009-2012 Alberta Energy Regulator, 2013 estimated by Clearstone Engineering Ltd. Conservation = [Volume of gas produced − (Volume of gas flared + Volume of gas vented)]. All reported flared volumes include gas that was incinerated. Venting = the non-combusted release of gas to the atmosphere.

Fugitive Emission Management Program

The Fugitive Emission Management Program detects, manages and repairs leaking equipment to reduce emissions, including volatile organic compounds (VOCs). It improves the Company's operating efficiency by tracking where and when leaks occur and linking to procurement strategies to improve future equipment purchases.

Fugitive emissions are hydrocarbon leaks from valves, piping connections, pumps and compressor seals and other piping system components that occur as part of the normal wear and tear in plant operations. Husky uses six highly specialized infrared cameras that can detect small emissions from long distances, providing a better view of normally inaccessible locations such as tank seals and overhead piping.