Safety Performance

Hardisty storage tank

Purpose and Progress

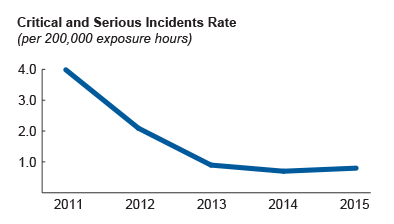

Husky delivers operational reliability and strengthens its safety record through rigorous occupational safety programs and ongoing improvements in process safety.

To enhance existing policies and procedures, the Company communicates the risks most associated with potential serious injuries and fatalities to employees and contractors so actions can be taken to mitigate those risks. The rate of critical and serious incidents per hours worked in 2015 was comparable to the year before.

Process Safety Events

Definitions of Tier 1, 2 and 3 process safety events are used to assess releases and other Loss of Primary Containment outcomes. Incidents are investigated to determine how to improve equipment reliability and related operating integrity practices.

These definitions align with those of the American Petroleum Institute, the American Institute of Chemical Engineers’ Center for Chemical Process Safety and the International Association of Oil and Gas Producers.

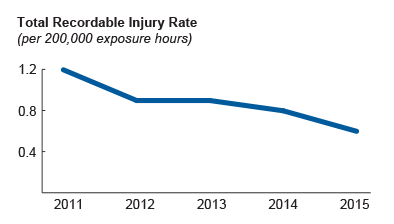

Total Recordable Injury Rate

The total recordable injury rate (TRIR) measures lost time, restricted work and medical aid incidents and fatalities.

Employees and contractors using clear procedures and processes to mitigate risk led to a lower TRIR rate. This rate has declined over the past four years. In 2015 Husky introduced programs to enhance its existing training, such as the International Organization of Oil and Gas Producers’ Life Saving Rules. These rules use consistent icons, with descriptive guidance, to reinforce simple actions that can mitigate risk when performing high risk activities.

In 2015, Husky achieved a 0.64 TRIR, which means there was less than 1.0 recordable injury per 100 workers per year, down from 0.80 the year before.

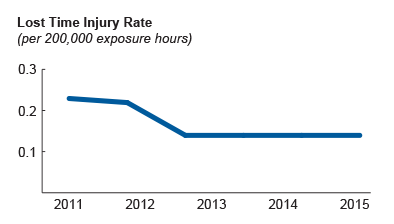

Lost Time Injuries

In 2015, the Company maintained a Lost Time Injury Rate of 0.14 per 200,000 exposure hours. Employees and contractors receive ongoing training in safety processes and procedures to continuously improve and drive this trend.

Husky continues to strengthen the safety culture at its worksites, by applying the Husky Operational Integrity Management System, a consistent, enterprise-wide approach to managing operations.

Driving

The Corporate Driving Standard includes mandatory driver training and vehicle monitoring devices that provide drivers with reports on their speed, seatbelt use and driving practices to improve performance.

In 2015, there were 48 employee motor vehicle accidents recorded, compared to 47 the year before. The Company’s fleet of approximately 1,500 vehicles covered almost 33 million kilometres.

Offshore

Husky’s well management program offshore Newfoundland and Labrador starts with the planning stage and continues through construction, commission and operation.

Wellbore monitoring, inspection of subsea trees, testing of subsurface safety equipment, plans for blowout mitigation and an inventory of relief well materials are part of the program. During operations, at least two independent and tested well barriers are in place.

The Company, with other area operators, participates in mutual emergency aid partnerships and a number of international safety initiatives.

Incident Tracking

A comprehensive incident tracking tool allows for ongoing monitoring and assessment of reported events to better prepare for potential operational incidents.

All “loss” and “no loss” (near-miss) events are tracked. Investigation results, action items and lessons learned are used for safety alerts, statistics reports, risk analysis, management reporting and training development.

Integrating the reporting and review of events such as injuries, equipment failures and complaints from the public can proactively reduce the probability of repeat events.

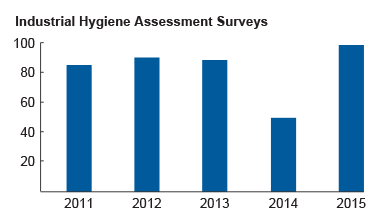

Industrial Hygiene

Identifying and controlling occupational health hazards allows Husky to understand potential exposures and better prevent the development of occupational illnesses.

In 2015, 98 surveys were completed, including samples taken from more than 1,300 employees or sites to assess exposure to potentially hazardous materials or environments. To improve its understanding of the effects of short-term exposure, the Company continues to collect short-term exposure data.

Husky is revising its Material Safety Data Sheets to align with a new international system. The Globally Harmonized System of Classification and Labelling of Chemicals will provide companies and workers with a single set of rules and label formats that are recognized by numerous jurisdictions. The new Safety Data Sheets will be compliant with this system.