The investment in the refinery rebuild is estimated to be more than $400 million US. Additional investments are being made in modifications and safety enhancements to the facility. The Superior Refinery directly employs about 200 workers and its $22.5 million annual payroll contributes to economic growth throughout the Superior-Duluth Region. This investment will ensure it can continue to contribute to the economy of the region for decades to come.

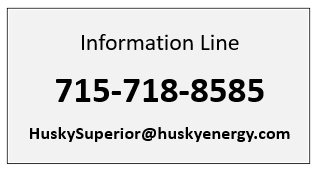

The Superior Refinery remains committed to its employees and the community. Our goal is to keep the community informed of our plans as they advance.

An open house is planned for Tuesday, April 16th from 5 p.m. to 8 p.m. at Superior Middle School to share the rebuild plans and timelines.

Key features of the project include:

- The refinery will be rebuilt with the same throughput capacity and once again be able to produce a full slate of products to service the region, including asphalt, gasoline, diesel and fuel oils.

- The rebuild will use Best Available Control Technology (BACT), which incorporates advances in technology and efficiencies made by the refining industry.

- The rebuilt facility will be more energy efficient and in full compliance with state and federal regulations.

- Construction is planned to begin in the Fall of 2019, with a target of resuming partial operations in late 2020.

- Local contractors and services will be employed in the rebuild whenever possible.

- The project is expected to create 350 jobs at peak during construction.

Ongoing use of hydrogen fluoride (HF) is proposed as part of the rebuild plan, with additional safety measures being implemented.

There was no release of HF during last year's fire and all safeguards worked as designed.

As to HF, additional safety enhancements, with regulatory approval, would include:

- A Rapid Acid Transfer System, that can be activated in the event of a leak to quickly transfer HF into an independent secure holding tank.

- Additional layers of water mitigation. The Superior Refinery currently has a water system that includes a dedicated curtain for the HF tank and two water cannons, which are a highly effective method of addressing hydrofluoric acid vapors. Additional curtains, pumps and water cannons are being proposed.

- Enhanced leak detection, including a dedicated area laser detection system and additional cameras.

HF is used to produce high octane gasolines which are an integral part of the refinery's product mix and economic viability. As part of the rebuild engineering and design phase, alternative alkylation options to HF were considered. This analysis included technology reviews, risk assessments, discussions with subject matter experts and site visits.

That analysis concluded the alternatives – either conversion to sulfuric acid alkylation or adoption of ISOALKY technology – were not commercially viable or introduced significant risks for the Superior Refinery.

- A conversion to sulfuric acid alkylation has never been done in the global refining industry and presents substantial technological and operational challenges. A conversion would also result in increased air emissions and greenhouse gases and would require a significant increase in sulfuric acid shipments with attendant transportation risks.

- ISOALKY technology is an emerging technology which has not yet been commercially proven in the refining industry. A commercial-size unit is being installed at a refinery in Salt Lake City, and we will continue to monitor and evaluate its progress over the longer term.

The Superior Refinery has safely used HF for almost 60 years. We understand the community's concerns about the ongoing use of HF and all of those who work at the refinery and live in the community are aware of the need to maintain the highest safety standards.

The refinery will continue to review new technologies and safety features that may be incorporated at the facility in the future.

This has been a difficult and challenging period for the refinery and its dedicated team of employees and contractors and we recognize our operations have a considerable impact on the community, as well. We are eager to get the refinery back to full operations and look forward to continuing to be an integral and contributing member of the Superior community.

Click here for more community updates.