Refinery Updates

April 3, 2019: Community Update

The Superior Refinery is making steady progress in its plans to return to full operations. Demolition work is now underway and it is expected that boots will be on the ground in the Fall of 2019 to begin construction on the refinery rebuild, pending regulatory approvals.

The investment in the refinery rebuild is estimated to be more than $400 million US. Additional investments are being made in modifications and safety enhancements to the facility. The Superior Refinery directly employs about 200 workers and its $22.5 million annual payroll contributes to economic growth throughout the Superior-Duluth Region. This investment will ensure it can continue to contribute to the economy of the region for decades to come.

The Superior Refinery remains committed to its employees and the community. Our goal is to keep the community informed of our plans as they advance.

An open house is planned for Tuesday, April 16th from 5 p.m. to 8 p.m. at Superior Middle School to share the rebuild plans and timelines.

Key features of the project include:

- The refinery will be rebuilt with the same throughput capacity and once again be able to produce a full slate of products to service the region, including asphalt, gasoline, diesel and fuel oils.

- The rebuild will use Best Available Control Technology (BACT), which incorporates advances in technology and efficiencies made by the refining industry.

- The rebuilt facility will be more energy efficient and in full compliance with state and federal regulations.

- Construction is planned to begin in the Fall of 2019, with a target of resuming partial operations in late 2020.

- Local contractors and services will be employed in the rebuild whenever possible.

- The project is expected to create 350 jobs at peak during construction.

Ongoing use of hydrogen fluoride (HF) is proposed as part of the rebuild plan, with additional safety measures being implemented.

There was no release of HF during last year's fire and all safeguards worked as designed.

As to HF, additional safety enhancements, with regulatory approval, would include:

- A Rapid Acid Transfer System, that can be activated in the event of a leak to quickly transfer HF into an independent secure holding tank.

- Additional layers of water mitigation. The Superior Refinery currently has a water system that includes a dedicated curtain for the HF tank and two water cannons, which are a highly effective method of addressing hydrofluoric acid vapors. Additional curtains, pumps and water cannons are being proposed.

- Enhanced leak detection, including a dedicated area laser detection system and additional cameras.

HF is used to produce high octane gasolines which are an integral part of the refinery's product mix and economic viability. As part of the rebuild engineering and design phase, alternative alkylation options to HF were considered. This analysis included technology reviews, risk assessments, discussions with subject matter experts and site visits.

That analysis concluded the alternatives – either conversion to sulfuric acid alkylation or adoption of ISOALKY technology – were not commercially viable or introduced significant risks for the Superior Refinery.

- A conversion to sulfuric acid alkylation has never been done in the global refining industry and presents substantial technological and operational challenges. A conversion would also result in increased air emissions and greenhouse gases and would require a significant increase in sulfuric acid shipments with attendant transportation risks.

- ISOALKY technology is an emerging technology which has not yet been commercially proven in the refining industry. A commercial-size unit is being installed at a refinery in Salt Lake City, and we will continue to monitor and evaluate its progress over the longer term.

The Superior Refinery has safely used HF for almost 60 years. We understand the community's concerns about the ongoing use of HF and all of those who work at the refinery and live in the community are aware of the need to maintain the highest safety standards.

The refinery will continue to review new technologies and safety features that may be incorporated at the facility in the future.

This has been a difficult and challenging period for the refinery and its dedicated team of employees and contractors and we recognize our operations have a considerable impact on the community, as well. We are eager to get the refinery back to full operations and look forward to continuing to be an integral and contributing member of the Superior community.

March 7, 2019: Community Update

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery's recovery. In partnership with community leadership, as well as municipal, state and federal agencies, we have made significant progress on site cleanup and demolition of damaged equipment. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

Our focus remains the safety of our workers and contractors, and the safety of the surrounding community. There will be fewer contractors on-site through the winter season, with about 350 employees and contractors supporting cleanup and demolition activities.

Demolition of piping near the damaged asphalt tanks will provide access so the remaining asphalt can be removed. The piping removal is 80 percent complete. Process unit demolition is expected to start around the end of March, as record snowfall and severe cold in February led to challenging working conditions and delayed demolition. The winterization of the refinery, including keeping equipment warm using steam from the boilers, has worked well.

In February, 183,000 barrels of light crude oil were transferred and sold via pipeline, completing the transfers of oil out of the refinery. The available asphalt has been moved via rail shipments, which will resume when additional product is removed from the damaged asphalt tanks.

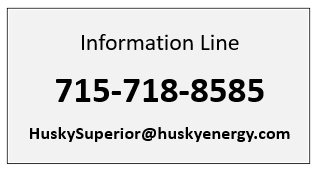

A residents' line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident. The toll-free number is: 1-855-527-5002. As of Thursday, Feb. 14, approximately 3,418 claims had been received. About 3,399 claims are closed and we are addressing those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR).

Air

The majority of the refinery de-inventory is now complete. Stationary monitors put in place in response to the fire and during de-inventory activities were demobilized on November 16th. Air monitoring continues on-site as needed. Additional site and/or community monitoring would be re-initiated if indicated by activities on site.

In addition to monitoring conducted by the U.S. EPA, the company's environmental consultant collected more than 208 million air quality readings in the community and at the refinery from April 26th to November 16th. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

The EPA and Husky's third-party consultant did not identify visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has provided soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health (pdf).

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek as winter conditions allow. The precautionary booms placed in Newton Creek were removed November 13th due to winter weather. To date, water samples collected from Newton Creek post-incident are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as per- and polyfluoroalkyl substances (PFAS).

Water collected during firefighting in response to the event, as well as during the recovery process, has been contained within the refinery's storm water and fire water ponds and is being treated within the on-site wastewater treatment plant (WWTP). Treated water from the WWTP is receiving further treatment from a system designed to remove PFAS-related compounds. This system consists of specialized granular activated carbon followed by a resin designed to target the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th, 2018. The treated water has intermittently been re-circulated to on-site ponds to maintain sufficient firefighting water capacity if needed. Through the winter, the WWTP and PFAS treatment system will remain in service, often in recirculation mode, which will further mitigate remaining PFAS concentrations in the on-site retention ponds.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are currently in place or immediately available. There have been no new impacts to wildlife since the previous update.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior, Wisconsin and does business under the licensed and registered trade name "Husky Energy".

February 1, 2019: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery's recovery. In partnership with community leadership, as well as municipal, state and federal agencies, we have made significant progress on site cleanup and demolition of damaged equipment. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

Our focus remains the safety of our workers and contractors, and the safety of the surrounding community. There will be fewer contractors on-site through the winter season, with about 350 employees and contractors supporting cleanup and demolition activities.

Demolition of piping near the damaged asphalt tanks will provide access so the remaining asphalt can be removed. The piping removal is 65 percent complete. Process unit demolition is expected to start in March.

The winterization of the refinery, such as keeping equipment warm using steam from the boilers, has worked well, including during severe cold in late January.

In December, 144,000 barrels of heavy crude oil were transferred and sold via pipeline. In January, the refinery began transferring light crude oil to be sold via pipeline. With shipping season over, the last Great Lakes vessel has been fueled at the Duluth Marine Terminal. Rail shipments have moved the available asphalt and will resume when additional product is removed from the damaged asphalt tanks.

A residents' line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident. The toll-free number is: 1-855-527-5002. As of Thursday, Jan. 17, approximately 3,417 claims had been received. About 3,398 claims are closed and we are addressing those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR).

Air

The majority of the refinery de-inventory is now complete. Stationary monitors put in place in response to the fire and during de-inventory activities were demobilized on November 16th. Air monitoring continues on-site as needed. Additional site and/or community monitoring would be re-initiated if indicated by activities on site.

In addition to monitoring conducted by the EPA, the company's environmental consultant collected more than 208 million air quality readings in the community and at the refinery from April 26th to November 16th. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

The EPA and Husky's third-party consultant did not identify visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has provided soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health (pdf).

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek as winter conditions allow. The precautionary booms placed in Newton Creek were removed November 13th due to winter weather. To date, water samples collected from Newton Creek post-incident are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as per- and polyfluoroalkyl substances (PFAS).

Water collected during firefighting in response to the event, as well as during the recovery process, has been contained within the refinery's storm water and fire water ponds and is being treated within the on-site wastewater treatment plant (WWTP). Treated water from the WWTP is receiving further treatment from a system designed to remove PFAS-related compounds. This system consists of specialized granular activated carbon followed by a resin designed to target the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th. The treated water has intermittently been re-circulated to on-site ponds to maintain sufficient firefighting water capacity if needed. Through the winter, the WWTP and PFAS treatment system will remain in service, often in recirculation mode, which will further mitigate remaining PFAS concentrations in the on-site retention ponds.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are currently in place or immediately available. There have been no new impacts to wildlife since the previous update.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior, Wisconsin and does business under the licensed and registered trade name "Husky Energy".

December 6, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery's recovery. In partnership with community leadership as well as municipal, state and federal agencies, we have made significant progress towards site stabilization and winterization of the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

Our focus remains the safety of our workers and contractors on-site, and the safety of the surrounding community. With turnaround and winterization activities substantially complete, the number of contractors and equipment on site has been reduced. About 350 employees and contractors are now supporting daily cleanup, recovery, winterization and site stabilization operations.

Asphalt recovery and removal continues with approximately 5,074 tons of asphalt recovered and removed from the site. Insulation damaged by the fire has been mostly removed from the process units and removal from piping near the asphalt tanks is underway.

Winterization of the process units is 95 percent complete, including draining lines to ensure they are free of water, preserving units with nitrogen caps and restoring steam tracing to keep the units warm.

Our remaining saleable gasoline and diesel fuel were moved off-site via pipeline in November and shipments of available asphalt were completed. We have started transferring asphalt from tanks in the damaged area, which will be available to ship by railcar in late 2018 and into 2019. Marine fuel will be trucked to the Duluth Marine Terminal until the shipping season ends.

Our response to questions and concerns raised at the Community Listening Session hosted by the University of Wisconsin – Extension has been posted here.

A residents' line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident. The toll-free number is: 1-855-527-5002. As of Tuesday, Nov. 20, approximately 3,413 claims had been received. Approximately 3,388 claims are closed and we are working to address those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation. The CSB is holding a town hall meeting in Superior on December 12 at the Yellowjacket Union on the University of Wisconsin Superior campus.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR).

Air

The majority of the refinery de-inventory is now complete. Stationary monitors put in place in response to the fire and during de-inventory activities were demobilized on November 16th. Air monitoring continues at site on an as-needed basis and additional site and/or community monitoring would be re-initiated if indicated by activities on site.

In addition to monitoring conducted by the U.S. EPA, the company's environmental consultant has collected more than 208 million air quality readings in the community and at the refinery from April 26th to November 16th. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

The EPA and Husky's third-party consultant did not identify visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has provided soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health.

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek. With the site stabilized and the arrival of winter weather, the precautionary booms placed in Newton Creek were removed November 13th. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as per- and polyfluoroalkyl substances (PFAS).

Water collected during firefighting in response to the event as well as during the recovery process has been contained within the refinery's storm water and fire water ponds and is being treated within the on-site wastewater treatment plant (WWTP). Treated water from the WWTP is receiving further treatment from a system designed to remove PFAS-related compounds. This system consists of specialized granular activated carbon followed by a resin designed to target the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th. The treated water has intermittently been re-circulated to on-site ponds in order to maintain sufficient firefighting water capacity if needed. Through the winter, the WWTP and PFAS treatment system will remain in service, however they will operate in recirculation mode, which will further mitigate remaining PFAS concentrations in the on-site retention ponds.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are currently in place or immediately available. There have been no new impacts to wildlife since the previous update.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior, Wisconsin and does business under the licensed and registered trade name "Husky Energy".

November 6, 2018: Community Update

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery's recovery. In partnership with community leadership as well as municipal, state and federal agencies, we have made significant progress towards site stabilization and we are making steady progress on the winterization of the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

Our focus remains the safety of our workers and contractors on-site, and the safety of the surrounding community. About 500 employees and contractors are now supporting daily cleanup, recovery and site stabilization operations.

Asphalt recovery and removal continues in areas with limited access, which results in a slower process. Approximately 4,825 tons of asphalt have now been recovered and removed from the site. Insulation damaged by the fire is also being removed.

Planned maintenance was completed in October, with most of those workers reassigned to facility winterization. Winterization of the process units is 75 percent complete, including draining lines to ensure they are free of water, preserving the units with nitrogen caps and restoring steam tracing to keep the units warm.

As well, we continue to move our existing saleable products off-site, with approximately 80 percent of the fuel products now removed. Marine fuel is being trucked to the Duluth Marine Terminal, asphalt is being shipped by railcars and, when appropriate, gasoline and diesel fuel are being moved to market by pipeline.

A residents' line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident, such as accommodations or transportation, and other related activities, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company's website.

As of Tuesday, Oct. 30, approximately 3,409 claims had been received. Approximately 3,379 claims are closed and we are working to address those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation. The Occupational Safety and Health Administration has completed its investigation and on October 2, issued citations to the refinery. Those citations have now been resolved.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

Air monitoring continues to take place in work areas when required and community monitoring would be re-initiated if on-site monitoring indicates a concern that could extend beyond the refinery fence line.

In addition to monitoring conducted by the U.S. EPA, the company's environmental consultant has collected more than 192 million air quality readings in the community and at the refinery. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

The EPA and Husky's third-party consultant did not identify visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has provided soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health.

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek. Booms continue to be used as a precautionary measure in the event of an unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as per- and polyfluoroalkyl substances (PFAS).

Water collected during firefighting in response to the event as well as during the recovery process has been contained within the refinery's storm water and fire water ponds and is being treated within the on-site wastewater treatment plant (WWTP). Treated water from the WWTP is receiving further treatment from a system designed to remove PFAS-related compounds. This system consists of specialized granular activated carbon followed by a resin designed to target the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th. The treated water has intermittently been re-circulated to on-site ponds in order to maintain sufficient firefighting water capacity if needed.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are currently in place or immediately available. A system using lasers mounted on tripods to create a programmed pattern has proven successful in deterring birds, particularly at night. Wildlife fatalities attributed to the event to date are two rabbits, one weasel, one fawn, three grackles, four robins, one starling, one American bittern, two geese, one redwing blackbird, four small unidentified birds and two frogs.

To date, one adult killdeer and two chicks, one robin and one water vole have been successfully cleaned and released. Additionally, three mallards, five geese and four goslings have been successfully treated and cleaned in the on-site rehabilitation facility and released at the Douglas County Wildlife Area. Several on-site families of geese have also been safely relocated to the wildlife area.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior, Wisconsin and does business under the licensed and registered trade name "Husky Energy".

October 1, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery's recovery. In partnership with community leadership as well as municipal, state and federal agencies, recovery continues and we are making steady progress towards stabilization and winterization of the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

About 600 employees and contractors are now supporting daily cleanup, recovery, site stabilization operations and planned maintenance activities. A central focus during this heightened period of site stabilization and recovery operations remains the safety of our workers and contractors on-site, and the safety of the surrounding community.

On September 15, a fill nozzle on a 1,000 gallon portable propane tank containing approximately 650 gallons of propane was damaged as it was being placed into position. A small amount of propane was released. As such, an exclusion zone was set up, workers were asked to leave the facility as a precaution and air monitoring was put in place. The tank was safely removed from site and de-inventoried.

Asphalt recovery and removal continues, with the focus on remaining areas with limited access. Approximately 4,704 tons of asphalt have now been recovered and removed from the site. Insulation damaged by the fire is also being removed.

Planned maintenance initially scheduled for May is expected to be completed by the middle of October and is a big step towards site stabilization and facility winterization.

We continue to de-inventory saleable products off-site to assist with winterization activities. Marine fuel is being trucked to the Duluth Marine Terminal, asphalt is being shipped by railcars and when appropriate gasoline and diesel fuel are being moved to market by pipeline.

A residents' line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident, such as accommodations or transportation, and other related activities, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company's website.

As of Tuesday, Sept. 25, approximately 3,405 claims had been received. Approximately 3,346 claims are closed and we are working to address those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation. The Occupational Safety and Health Administration has completed its work on-site and Husky continues to work with it on any follow-up matters.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

Air monitoring is occurring within the facility while recovery activities are taking place on-site. Community monitoring would be re-initiated if on-site monitoring indicates a concern that could extend beyond the refinery fence line.

In addition to monitoring conducted by the U.S. EPA, the company's environmental consultant has collected more than 153 million air quality readings in the community and at the refinery. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

The EPA and Husky's third-party consultant did not identify visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has provided soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health.

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek. Booms continue to be used as a precautionary measure in the event of an unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting in response to the event as well as during the recovery process has been contained within the refinery's storm water and fire water ponds and is being treated within the on-site wastewater treatment plant (WWTP). Treated water from the WWTP is receiving further treatment from a system designed to remove PFAS-related compounds. This system consists of specialized granular activated carbon followed by a resin designed to target the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th. The treated water has intermittently been re-circulated to on-site ponds in order to maintain sufficient firefighting water capacity if needed.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, using lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. Wildlife fatalities attributed to the event to date are two rabbits, one weasel, one fawn, three grackles, four robins, one starling, one American bittern, two geese, one redwing blackbird, four small unidentified birds and two frogs.

To date, one adult killdeer and two chicks, one robin and one water vole have been successfully cleaned and released. Additionally, three mallards, five geese and four goslings have been successfully treated and cleaned in the on-site rehabilitation facility and released at the Douglas County Wildlife Area. Several on-site families of geese have also been safely relocated to the wildlife area.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior, Wisconsin and does business under the licensed and registered trade name "Husky Energy".September 4, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery’s recovery. In partnership with community leadership as well as municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety precautions, recovery efforts and environmental mitigation and monitoring results.

Asphalt removal from the process units and the asphalt tank farm has largely been completed, with some cleanup work remaining in areas with limited access.The crews are now focused on removing insulation damaged by the fire. Approximately 4,400 tons of asphalt have now been removed from the site. Significant progress has also been made in removing asphalt from the storm water sewers.

The planned maintenance initially scheduled for May began on July 30th, bringing an increased number of contractors to site. Based on a revised schedule, the work is expected to be completed in October and will be a big step towards site stabilization and facility winterization.

Refinery personnel are assessing and repairing assets, where possible. About 600 employees and contractors are now supporting daily cleanup, recovery, site stabilization operations and planned maintenance activities.

The Superior Terminal is shipping marine fuel to the Duluth Marine Terminal. As well, de-inventory of asphalt from tanks not damaged during the incident has begun via railcar loading.

A residents’ line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company’s website.

As of Wednesday, Aug. 28, approximately 3,392 claims had been received. Approximately 3,335 claims are closed and good progress is being made in addressing those remaining.

Investigations

The Chemical Safety Board (CSB) has released 13 of 14 units from its investigation. The Occupational Safety and Health Administration has completed its work on-site and Husky continues to work with it on any follow-up matters.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

Air monitoring is occurring within the facility while recovery activities are taking place on-site. Community monitoring would be re-initiated if on-site monitoring indicates a concern that could extend beyond the refinery fence line.

In addition to monitoring conducted by the U.S. EPA, the company’s environmental consultant has collected more than 125 million air quality readings in the community and at the refinery. All community monitoring indicated concentrations below health-based thresholds. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, the EPA and Husky’s third-party consultant have not identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has soil and gardening health information on its website, along with a memo from the Wisconsin Department of Health.

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek. Booms continue to be used as a precautionary measure in the event of an unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting in response to the event is contained within the refinery’s storm water and fire water ponds and is being treated within the on-site wastewater treatment plant. It is also going through an additional treatment system designed to remove PFAS-related compounds, consisting of specialized granular activated carbon followed by a resin that further targets the removal of PFAS compounds. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th. The treated water has intermittently been re-circulated to on-site ponds in order to maintain sufficient firefighting water capacity if needed.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, using lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. An animal rehabilitation facility, authorized by U.S. Fish and Wildlife Service, treats wildlife impacted by the incident on site. Wildlife fatalities attributed to the event to date are two rabbits, one weasel, one fawn, three grackles, four robins, one starling, one American bittern, two geese, one redwing blackbird, two small unidentified birds and two frogs.

To date, one adult killdeer and two chicks, one robin and one water vole have been successfully cleaned and released. Additionally, three mallards, five geese and four goslings have been successfully treated and cleaned in the on-site rehabilitation facility and released at the Douglas County Wildlife Area. Several on-site families of geese have also been safely relocated to the wildlife area.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin,and does business under the licensed and registered trade name “Husky Energy”.

August 2, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery’s recovery. In partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, recovery efforts and environmental mitigation and monitoring results.

Five crews working on removing asphalt that spilled from a damaged tank during the initial incident have been making steady progress, with removal complete for most process units. Approximately 3,300 tons have now been removed from the site.

Refinery personnel are completing cleanup of the associated areas and have started assessing and repairing assets. About 450 employees and contractors are now supporting daily cleanup, recovery and site stabilization operations.

Work to de-inventory hydrocarbons from various processing units continues, with approximately 14 of 15 de-inventory programs now completed. Work on the final unit was divided into two phases, increasing the number of de-inventory programs to 15 from 14.

We are working towards returning the Superior Terminal to service. Work is underway to restore communications to the refinery’s truck loading rack, with the expectation that trucks will again be loaded at the Marketing Terminal in August. This may result in truck traffic similar to that experienced under normal operating conditions.

A steam-generating boiler was re-started in July to assist with cleanup activities and the ongoing de-inventory program, including the asphalt tank farm. Residents may notice steam being produced and as part of the recovery effort.

A residents’ line is available between 8 a.m. and 4 p.m. to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company’s website.

As of Monday, July 30, approximately 3,379 claims had been received. Approximately 3,253 claims are closed and good progress is being made in addressing those remaining.

Investigations

The Chemical Safety Board (CSB) has released 12 of 14 units from its investigation. The Occupational Safety and Health Administration has completed its work on-site and Husky continues to work with it on any follow-up matters.

On Aug. 2nd the CSB released an update to its investigation into the cause of the April 26th incident. Husky has reviewed the Factual Update and will continue to work with the CSB to understand the root cause. While the CSB update is preliminary and does not answer all questions, the CSB’s investigation is important to understanding what happened.

The safety of our employees and the community remains our top priority and we will continue to work collaboratively with the CSB and other investigating agencies. The lessons learned will assist with our decisions as we begin the process of rebuilding. While the refinery is not expected to resume normal operations for at least 18 to 24 months, we remain committed to our employees and the community and there will be no layoffs as a result of this incident.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

Community air monitoring was discontinued on June 19th. All community monitoring had indicated concentrations below health-based thresholds. Monitoring within the facility will continue while recovery activities are taking place on-site, with community monitoring re-initiated if on-site monitoring indicates a concern that could extend beyond the refinery fence line.

In addition to monitoring conducted by the U.S. EPA, the company’s environmental consultant has collected more than 87 million air quality readings in the community and at the refinery. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, the EPA and Husky’s third-party consultant have not identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has soil and gardening health information on its website, along with an additional updated memo from the Wisconsin Department of Health.

Water

The company is regularly collecting surface water samples from the on-site storm water and fire water ponds, and at multiple locations along the length of Newton Creek. Booms continue to be used as a precautionary measure in the event of an unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting in response to the event is contained within the refinery’s storm water and fire water ponds and is being treated within the on-site wastewater treatment plant. An additional treatment system designed to remove PFAS-related compounds, which began operating on May 25, consists of specialized granular activated carbon followed by a resin that further targets the removal of PFAS compounds. A second PFAS treatment system has been in place since early July to provide additional treatment capacity for PFAS impacted water as needed. The wastewater treatment plant began discharging treated water to Newton Creek on May 29th, however due to the lack of recent precipitation, treated water is currently re-circulating to the storm water and fire water retention ponds. Once there is sufficient precipitation to maintain charge to the waste water treatment plant, treated water will again be routed to Newton Creek.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, using lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. An animal rehabilitation facility, authorized by U.S. Fish and Wildlife Service, treats wildlife impacted by the incident on site. Wildlife fatalities attributed to the event to date are two rabbits, one weasel, one fawn, three grackles, three robins, one starling, one American bittern, two geese, one redwing blackbird, two small unidentified birds and two frogs.

To date, one adult killdeer and two chicks have been successfully cleaned and released. Additionally, three mallards, five geese and four goslings have been successfully treated and cleaned in the on-site rehabilitation facility and released at the Douglas County Wildlife Area. Several on-site families of geese have also been safely relocated to the wildlife area.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin,and does business under the licensed and registered trade name “Husky Energy”.

July 1, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees on the Superior Refinery’s recovery. In partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, recovery efforts and environmental mitigation and monitoring results.

On June 19th, with critical activities completed on site, including the safe removal of the tower that had been damaged and was being secured, regulatory agencies were notified that Incident Command was stood down. Staff previously operating out of the Emergency Operations Center on Hammond Avenue are now working at the refinery, with about 400 employees and contractors now supporting daily operations.

Five crews working on removing asphalt that spilled from a damaged tank during the initial incident have been making steady progress. Approximately 2,500 tons have now been removed from the site.

The Chemical Safety Board continues to progress its investigation into the cause of the April 26th incident. The CSB has released 10 of 14 units from its investigation. Refinery personnel are completing cleanup of the associated areas and have started assessing and repairing assets.

The Occupational Safety and Health Administration has completed its work on site. Husky continues to work with OSHA on any follow-up matters.

Work to de-inventory hydrocarbons from various processing units continues, with approximately 11 of 14 de-inventory programs now completed.

We are working towards returning the Superior Terminal to service. Work is underway to restore communications to the refinery’s truck loading rack, with the expectation that in July trucks will again be loaded on site until stored inventory is removed. Consequently, this may result in truck traffic similar to that experienced under normal operating conditions.

We expect to re-start a steam-generating boiler in early July, which will assist with cleanup activities and the ongoing de-inventory program, as well as facilitate moving asphalt off site. Once the boiler is re-started, residents may notice steam being produced and used at the site.

The company continues to maintain a 24-hour residents’ line to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company’s website.

As of Friday, June 30th, 3,323 claims had been received. Approximately 2,707 claims are now closed and good progress is being made in addressing the remaining claims.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

As of June 19th, 2018, with critical activities completed on site, the company discontinued its community air monitoring. All community monitoring indicated concentrations below health-based thresholds. Monitoring within the facility will continue while recovery activities are taking place on-site, with community monitoring re-initiated if on-site monitoring indicates a concern that could extend beyond the refinery fence line.

In addition to monitoring conducted by the U.S. EPA, the company’s environmental consultant has collected more than 55 million air quality readings in the community and at the refinery. The historical results of the community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, the EPA and Husky’s third-party consultant have not identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has soil and gardening health information on its website.

Water

The company is regularly collecting surface water samples from the on-site storm water ponds, and at multiple locations along the length of Newton Creek. Booms continue to be used as a precautionary measure in the event of an unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam, collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting in response to the event is contained within the refinery’s storm water and fire water ponds and is being treated within the on-site wastewater treatment plant. A treatment system designed to remove PFAS-related compounds, which began operating on May 25th, is also being used, consisting of specialized granular activated carbon followed by a resin that further targets the removal of PFAS compounds. A second PFAS treatment system is expected to be in place in early July, further increasing site processing capacity. The wastewater treatment plant began routing treated water to Newton Creek on May 29th.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, using lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. An animal rehabilitation facility, authorized by U.S. Fish and Wildlife Service, treats wildlife impacted by the incident on site. Wildlife fatalities attributed to the event to date are two rabbits, one weasel, one fawn, three grackles, three robins, one starling, one American bittern, two geese, one small unidentified bird and two frogs. To date, three mallards, five geese and four goslings have been successfully treated and cleaned in the facility and released at the Douglas County Wildlife Area. Several families of geese on site have also been safely relocated to the wildlife area.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin,and does business under the licensed and registered trade name “Husky Energy”.

June 9, 2018: Community Update

The Husky Superior Refinery held a community update and open house on Tuesday, June 5th at the Superior Middle School. The event was attended by approximately 150 area residents and we greatly appreciated the opportunity to provide an update on our work to safely secure the site and outline the path forward. We would like to thank residents and members of the local business community who attended, as well as the representatives from county, state and federal agencies who were on hand to answer questions.

We will continue to provide updates on progress at the refinery on our website. As the work is now more incremental, we will be moving to a monthly update.

In addition, a community newsletter was distributed to all Superior residents this week. An electronic version is available on the Husky Energy website.

Overview

Husky Energy continues to work with the community, government agencies and its employees to recover. In partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, recovery efforts and environmental mitigation and monitoring results.

Crews have been making steady progress in removing asphalt that spilled from a tank breached in the initial incident. Three additional crews are now on site, for a total of five, providing for an increased rate of removal. Approximately 1,300 tons have now been removed.

About 400 employees and contractors are at the refinery site daily, and about 30 people continue to staff the Emergency Operations Center on Hammond Avenue in Superior. Approximately five workers are in the community, performing such tasks as air monitoring, claims processing and debris cleanup.

The Chemical Safety Board continues to progress its investigation into the cause of the April 26th incident. The CSB this week released 10 of 14 units from its investigation. This will allow workers to complete cleanup of the associated areas and facilitate assessment and repair of the assets.

The Occupational Safety and Health Administration (OSHA) has completed its work on site. Husky will continue to work with OSHA on any follow-up matters.

Work to de-inventory hydrocarbons from various processing units on site continues. Approximately 8 of 14 de-inventory programs are now completed.

A large crane on site is securing a tower damaged in the initial incident which was leaning. The tower has been secured and hydrocarbons are being removed. Once completed, the tower will be removed.

A shipment of 47,000 barrels of gasoline (2 million gallons) was delivered this week from a storage tank on site to the company’s Esko terminal for sale to customers.

The company continues to maintain a 24-hour residents’ line to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is available on the company’s website. However, different release forms may be used to fit specific needs and situations.

As of Saturday morning, June 9, approximately 2,993 claims had been received. Approximately 2,265 claims are now closed and good progress is being made in addressing the remaining claims.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

The company continues environmental monitoring at the refinery and around the community. There are 26 fixed monitors placed on the fence line, encircling the facility. Within the refinery, fixed monitors are being supplemented by mobile monitoring as hydrocarbon removal proceeds. One mobile community monitoring team is in place when active de-inventory work is being completed at the refinery.

In addition to monitoring conducted by the U.S. EPA, the company’s environmental consultant has collected more than 34 million air quality readings in the community and at the refinery. This past week, air quality monitoring was conducted at approximately 700 individual locations in the community. None of the monitoring has shown concentrations above health-based thresholds. The results of this community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, neither EPA nor Husky’s third-party consultant have identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has prepared an update regarding soil and gardening health information, which is also available on its website.

Water

The company is regularly collecting surface water samples from the onsite storm water ponds, and at multiple locations along the length of Newton Creek. Booms will continue to be used as a precautionary measure to help contain any unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting is being contained within the refinery’s storm water and fire water containment system. Water is now being treated within the wastewater treatment plant and also through the PFAS treatment system which began operating on May 25. This is an important step in our management of firefighting water retained on site. The PFAS treatment system consists of specialized granular activated carbon followed by a resin that can further target the removal of PFAS compounds. The wastewater treatment plant began routing the treated water to Newton Creek on May 29.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, which uses lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. An animal rehabilitation facility has been authorized by U.S. Fish and Wildlife Service and set up on site to treat wildlife impacted by the incident. Wildlife fatalities to date are one common grackle, one crow, one small unidentified bird, one weasel, one deer and two frogs. Two oiled mallards and three oiled geese were successfully treated and cleaned in the facility and have been released at the Douglas County Wildlife Area. Two additional oiled geese were taken into care this week and are currently in the on-site rehabilitation center receiving treatment prior to release.

Debris

If you have debris on your property that you believe is associated with the refinery, please contact us at: 1-855-527-5002. We will collect this material as it is identified.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin,and does business under the licensed and registered trade name “Husky Energy”.

June 3, 2018: Community Update

The Husky Superior Refinery will hold a community update and open house on Tuesday, June 5th from 4:30 to 8 p.m. at the Superior Middle School, 3625 Hammond Ave. Superior Refinery representatives, as well as experts from county, state and federal agencies will be on hand to answer questions on a variety of topics, including the current status at the refinery and the path ahead, and to address concerns related to health, air, water, soil and more.

Overview

Husky Energy continues to work with the community, government agencies and its employees to recover. In partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This update for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, recovery efforts and environmental mitigation and monitoring results.

Crews have been making steady progress in removing asphalt that spilled from a tank breached in the initial incident. Three additional crews are now on site, for a total of five, providing for an increased rate of removal. Approximately 850 tons have now been removed.

About 400 employees and contractors are at the refinery site daily, and about 40 people continue to staff the Emergency Operations Center on Hammond Avenue in Superior. Approximately five workers are in the community, performing such tasks as air monitoring, claims processing and debris cleanup.

Work to de-inventory hydrocarbons from various processing units on site continues. Approximately 6 of 14 de-inventory programs are now completed. This includes the benzene reduction unit, green gas unit, FCC main column receiver, propane treater/sand filter and the high-pressure receiver and condensers. Ammonia and chlorine on site have been also removed.

A large crane on site is securing a tower damaged in the initial incident which was leaning. The tower has been secured and hydrocarbons are being removed. Once completed, the tower will be removed.

Stinson Avenue is reopen to regular traffic. Residents using the road should be aware that there may occasionally be a need for temporary road closures to accommodate work on site.

The company continues to maintain a 24-hour residents’ line to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is now available on the company’s website. However, different release forms may be used to fit specific needs and situations.

As of Saturday morning, June 2, approximately 2,867 claims had been received. Approximately 2,090 claims are now closed and good progress is being made in addressing the remaining claims.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, including the U.S. Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

The company continues environmental monitoring at the refinery and around the community. There are 26 fixed monitors placed on the fence line, encircling the facility. Within the refinery, fixed monitors are being supplemented by mobile monitoring as hydrocarbon removal proceeds. One mobile community monitoring team is in place when active de-inventory work is being completed at the refinery.

In addition to monitoring conducted by the U.S. EPA, the company’s environmental consultant has collected more than 27 million air quality readings in the community and at the refinery. This past week, air quality monitoring was conducted at approximately 700 individual locations in the community. None of the monitoring has shown concentrations above health-based thresholds. The results of this community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, neither EPA nor Husky’s third-party consultant have identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has prepared an update regarding soil and gardening health information, which is also available on its website.

Water

The company is regularly collecting surface water samples from the onsite storm water ponds, and at multiple locations along the length of Newton Creek. Booms will continue to be used as a precautionary measure to help contain any unexpected discharge. Water samples collected from Newton Creek post-incident to date are comparable to baseline samples collected prior to the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam collectively known as Perfluoroalkyl Sulfonate (PFAS).

Water collected during firefighting is being contained within the refinery’s storm water and fire water containment system. Water is now being treated within the wastewater treatment plant and also through the PFAS treatment system which began operating on May 25. This is an important step in our management of firefighting water retained on site. The PFAS treatment system consists of specialized granular activated carbon followed by a resin that can further target the removal of PFAS compounds. The wastewater treatment plant began routing the treated water to Newton Creek on May 29.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging, canine patrols and laser stations are in place. A laser light system, which uses lasers mounted on tripods to create a programmed pattern, has proven successful in deterring birds, particularly at night. An animal rehabilitation facility has been authorized by U.S. Fish and Wildlife Service and set up on site to treat wildlife impacted by the incident. Wildlife fatalities to date are one common grackle, one crow, one small unidentified bird, one weasel, one deer and two frogs. Two oiled mallards and three geese were successfully treated and cleaned in the facility and have been released at the Douglas County Wildlife Area.

Debris

If you have debris on your property that you believe is associated with the refinery, please contact us at: 1-855-527-5002. We will collect this material as it is identified.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin,and does business under the licensed and registered trade name “Husky Energy”.

May 26, 2018: Community Update

The Husky Superior Refinery will hold a community update and open house on Tuesday, June 5th from 4:30 to 8 p.m. at the Superior Middle School, 3625 Hammond Ave. Superior Refinery representatives, as well as experts from county, state and federal agencies will be on hand to answer questions on a variety of topics, including the current status at the refinery and the path ahead, and to address concerns related to health, air, water, soil and more.

One Month Update

Husky Energy continues to work with the community, government agencies and its employees to recover. Working in partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This progress report for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, environmental mitigation, recovery efforts and environmental monitoring results.

It has been one month since the initial fire on April 26th, and while substantial work still needs to take place to secure and stabilize the site, the passing of one month provides an opportunity to summarize activities to date.

The initial fire knocked out electricity to most areas of the refinery site. Over the past month, crews have been able to systematically secure buildings and processing units and safely restore power. Most areas of the refinery, including such key operations areas as the wastewater treatment plant, administration and maintenance buildings, and various control centers have been reenergized. This also includes restoring lighting to the Federal Aviation Administration lights on the boiler stack and restoring the automatic electric firefighting systems. The automatic fire fighting systems were operating on backup diesel generated power, but are now on the primary electricity-powered system. Only a few smaller buildings, which are in the area restricted for further investigation, remain to have power restored. In addition, power has been disconnected from the damaged processing units to ensure they cannot be inadvertently energized.

Crews have been making steady progress in removing asphalt that had been spilled from a tank breached in the initial incident. Approximately 65,360 square feet of asphalt, or about 642 tons, has now been removed. Work continues to remove the remainder of the asphalt on site, with about 40 percent of the covered area now cleared.

Approximately 400 employees and contractors are at the refinery site daily, and about 50 continue to staff the Emergency Operations Center on Hammond Avenue in Superior. Approximately 10 workers are in the community, performing such tasks as air monitoring, claims processing and debris cleanup.

Work to de-inventory hydrocarbons from various processing units on site continues. Approximately 5 of 14 de-inventory programs are now completed. This includes the benzene reduction unit, green gas unit, FCC main column receiver, and propane treater/sand filter. Ammonia and chlorine on site have been also removed.

A large crane arrived on site earlier in the month to secure a tower which was damaged in the initial incident and was leaning. The tower has been secured and hydrocarbons are being removed. Once completed, the tower will be removed.

Stinson Avenue has been reopened to regular traffic. Residents using the road should be aware that there may occasionally be a need for temporary road closures to accommodate work on site.

The company continues to maintain a toll-free 24-hour residents’ line to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is now available on the company’s website. However, different release forms may be used to fit specific needs and situations.

As of Saturday morning, May 26, approximately 2,781 claims had been received. Approximately 2,000 claims are now closed and good progress is being made in addressing the remaining claims. In many cases, we have been able to issue payments by direct deposit, or via check with claims adjusters on site at a local hotel.

Environmental Overview

We continue to cooperate fully with environmental and regulatory agencies, such as the US Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (WDNR), which are conducting independent responses to the incident.

Air

The company continues environmental monitoring at the refinery and around the community. There are 26 fixed monitors placed on the fence line, encircling the facility. Within the refinery, fixed monitors are being supplemented by mobile monitoring as hydrocarbon removal proceeds. Two mobile air monitoring teams are continuously collecting air quality data in the community.

In addition to monitoring conducted by the US EPA, the company’s environmental consultant has collected more than 20 million air quality readings in the community and at the refinery. This past week, air quality monitoring was conducted at approximately 5,600 individual locations in the community. None of the monitoring has shown concentrations above health-based thresholds. The results of this community monitoring program can be found on the Douglas County Department of Health and Human Services website.

To date, the EPA has not identified visible community soot deposition from the incident. The Douglas County Department of Health and Human Services has prepared an update regarding soil and gardening health information, which is also available on its website.

Water

Water collected during firefighting is being contained within the refinery’s storm water and fire water containment system. Water is now being treated within the wastewater treatment plant, which is an important step in our management of water retained on site. The company is regularly collecting surface water samples from the onsite storm water ponds, and at multiple locations along the length of Newton Creek. Booms will continue to be used as a precautionary measure to help contain any unexpected discharge. Water samples collected post-incident to date are comparable to baseline samples collected before the incident under normal refinery operating conditions, with the exception of trace amounts of chemical components found in firefighting foam collectively known as Perfluoroalkyl Sulfonate (PFAS). A PFAS treatment plan is in development with WDNR. Specialized carbon treatment and resin units arrived on site this week and are now tied into the water treatment system. Samples have been sent to a laboratory to test the efficacy of the carbon and resin treatment systems for addressing PFAS and results are expected soon. We will seek approval from the WDNR before discharging the treated water from this system.

Wildlife

Protections and deterrents for wildlife, including fencing, flagging and canine patrols, continue to be implemented as part of the response. An additional deterrent measure was implemented this week to further deter birds. A laser light system, which uses a programmed pattern with lasers mounted on tripods, will be deployed next week. The laser movements have proven successful in deterring birds, particularly at night. An animal rehabilitation facility has been authorized by U.S. Fish and Wildlife Service and set up on site to treat wildlife impacted by the incident. Wildlife fatalities to date are one common grackle, one crow, one small unidentified bird, one weasel and two frogs. Two oiled mallards and one goose were successfully treated and cleaned in the facility and were released at the Douglas County Wildlife Area Friday afternoon. The three birds were observed calmly leaving their pens and entering the marsh. Two additional geese are now receiving treatment and will be released upon completion.

Debris

Collection of debris outside the fence line from the refinery incident is largely complete.

If you have debris on your property that you believe is associated with the refinery, please contact us at the toll-free number: 1-855-527-5002. We will continue to collect this material as it is identified.

Superior Refining Company LLC is the owner and operator of the refinery located in Superior Wisconsin, and does business under the licensed and registered trade name “Husky Energy”.

May 19, 2018: Community Update

Overview

Husky Energy continues to work with the community, government agencies and its employees to recover. Working in partnership with community leadership, municipal, state and federal agencies, we continue to make progress towards the goal of securing and stabilizing the refinery. This progress report for the community is intended to keep Superior stakeholders apprised of ongoing safety requirements, environmental mitigation, recovery efforts and environmental monitoring results. Approximately 400 employees and contractors are at the refinery site daily, and about 50 people are staffing the Emergency Operations Center on Hammond Avenue in Superior. Approximately 10 workers are in the community, performing such tasks as air monitoring, claims processing and debris cleanup.

Electricity is restored to a number of buildings at site, including the boiler house control room and crude control room. Last week, 17 buildings on site were inspected and cleared for access.

We continue to clear areas within and around the facility to facilitate cleanup and the next phases of work. Additional hydrocarbon removal plans were developed this week and work continues to de-inventory various areas of the site. On Wednesday, the on-site ammonia tank was emptied and on Thursday gasoline was removed from the hydrogen gasoline desulfurization unit.

A large crane arrived on site last Saturday to secure the stripper tower. The tower is now secured and scheduled for de-inventory this week.

On Thursday, Stinson Avenue reopened to traffic. We ask drivers to lower their speeds and refrain from stopping when travelling past the refinery due to ongoing work at the site. Residents using the road should be aware that there may occasionally be a need for temporary road closures to accommodate safe work on site.

The company has a toll-free 24-hour residents’ line to assist with claims related to the incident, such as accommodation or transportation, and other supports, including access to counselling. The toll-free number is: 1-855-527-5002. A liability waiver is only required for injury claims and only once a satisfactory settlement has been reached. The standard release is now available on the company’s website. However, different release forms may be used to fit specific needs and situations.