Air Quality

Emissions

Husky is working to reduce its emissions, including capturing carbon dioxide, minimizing fugitive emissions and mitigating flaring and venting, as well as reducing its energy consumption.

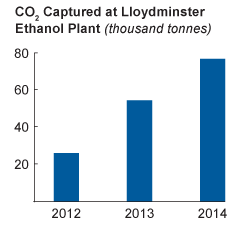

Carbon dioxide is captured at the Company’s Lloydminster Ethanol Plant to aid in enhanced oil recovery (EOR), which involves CO2 being injected to increase oil production. More than 150,000 tonnes of CO2 captured between 2012 and December 2014 have been used for EOR in heavy oil fields. The Company continues to investigate additional opportunities to use captured CO2 for oil recovery.

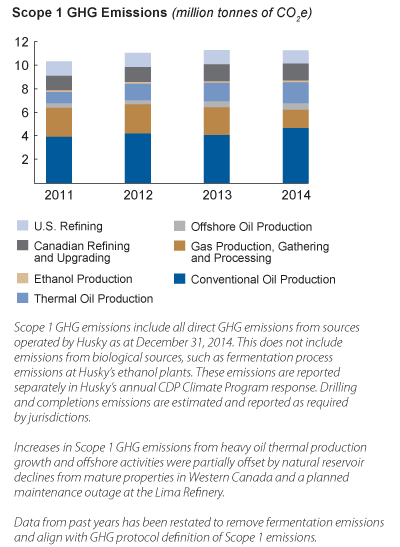

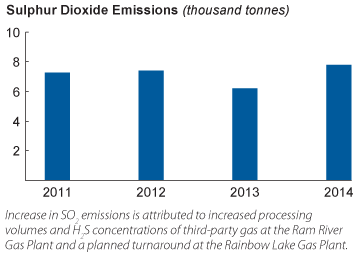

The Company measures and reports greenhouse gas (GHG) emissions and criteria air contaminants, such as sulphur dioxide (SO2) emissions. This provides an opportunity to forecast and evaluate reported emissions at the corporate and individual facility level.

Air quality and carbon management programs achieve regulatory compliance and are supported by Husky’s Environmental Performance Reporting System, providing for transparency and ensuring consistent data.

Gas Conservation

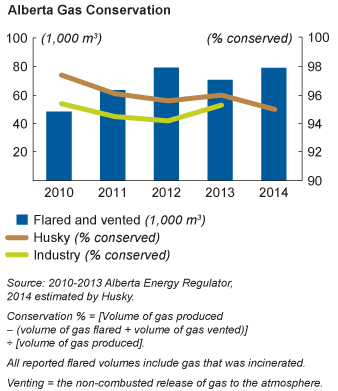

The Company estimates overall solution gas conservation at its Alberta operations in 2014 was 95 percent. Data from the annual Alberta Energy Regulator’s Upstream Petroleum Industry Flaring and Venting Report shows Husky’s gas conservation in the province between 2010 and 2013 was above the industry average.

Fugitive Emission Management Program

The Fugitive Emission Management Program detects and repairs leaking equipment to reduce emissions. It improves the Company’s operating efficiency by tracking where and when leaks occur and is linked to procurement strategies to inform future equipment purchases.

Fugitive emissions are hydrocarbon leaks, including volatile organic compounds (VOCs), from valves, piping connections, pumps and compressor seals and other piping system components that occur as part of the normal operation of a plant. Husky uses a number of techniques to detect leaking components, including highly specialized infrared cameras that provide a view of normally inaccessible locations such as tank seals and overhead piping from a distance, and ultrasonic detection, which identifies leaking components using sound. Vapour analyzers and ultrasonic measurements can be used to quantify an emission.

Data on fugitive emissions is stored in a central system, allowing for timely notification of surveys and repairs, and the tracking of components and reporting.